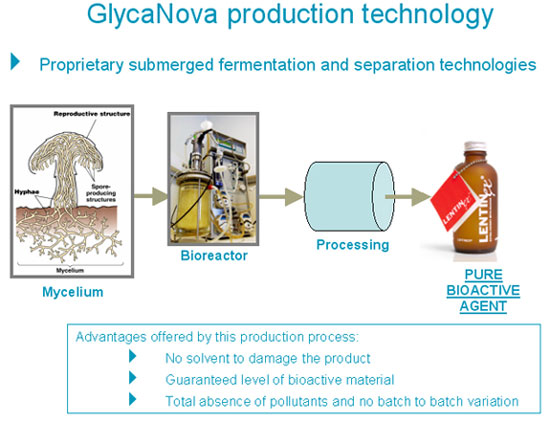

Our nutraceutical/pharmaceutical partners in Norway have developed a proprietary production technology based on submerged fermentation and product isolation technology. The use of submerged fermentation allows complete control of the production process and ensures that there are no undesirable compounds in any of the product streams whether the streams are intended for nutraceutical or pharmaceutical products. The main product, beta glucan, is retained in its native three dimensional structure, a prerequisite for high level of bioactivity. Furthermore, the beta glucan is soluble, which means it is easily absorbed by the body.

Production of nutraceuticals

After the fermentation process, the biomass is separated from the fermentation liquor, leading to two different product streams, one containing the biomass and the other containing the extracellular products. Both streams can be used as nutraceuticals without further processing. For selected application areas, the liquid stream is transferred to product finishing steps.

Production of pharmaceuticals

For pharmaceutical grade products, the fermentation broth undergoes further processing. Depending on the nature of the fermentation broth and the product isolation steps employed, several pharmaceutical grade products can be generated from the same fermentation broth. Solvent extraction is not part of any of the processing steps.